The injection mold making always helps to provide bucketful of advantages to the companies which implement these kinds of procedures. Injection molding is considered to be one of the most commonly utilized methods of producing identical products of plastic, especially in the higher volumes. It is very much important for people to understand the very specific design restrictions to implement this particular concept so that one can successfully produce high-quality and cost-effective parts.

Following are some of the multiple advantages provided by the concept of injection molding:

-With the implementation of this particular concept the companies will be able to make sure that they will be able to produce a great number of parts per hour. The speed will always depend on the size and complexity of the world but approximately this particular concept comes with the speed of more than 15-120 per cycle time.

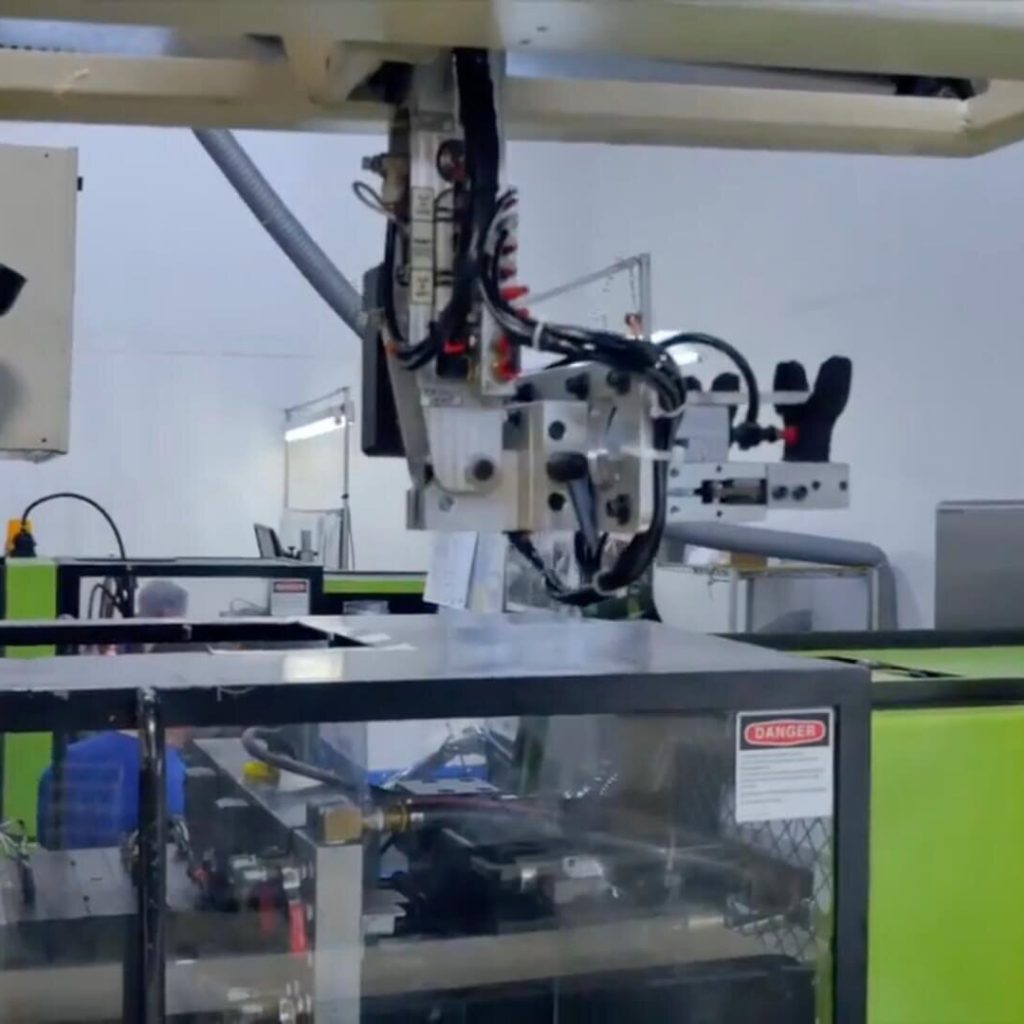

-Everything is based upon the lower cost of labor that further makes sure that everything will be performed by machines and robotics. Hence, everything will be operated by a single operator which will help in saving a lot of cost of the companies which will make sure that overheads will be significantly reduced at the end of the whole process.

-The flexibility designing will be perfectly done and the mold themselves will be able to deal with extremely high pressure. There will be more chances of details being imprinted on the parts which will further make sure that complex designs will be easily manufactured and there will be a higher level of flexibility in the whole system. The best benefit associated with the whole process is that thousands of parts can be easily produced before the tooling needs to be maintained.

-There will be proper material choices among the people because the large selection of polymer is very well available for the people to be chosen from. These kinds of multiple plastic parts can also be utilized simultaneously which is another great benefit of the whole process.

-The injection molding produces very little amount of postproduction waste and the scrap rates are very low. This particular point makes it very much preferable in comparison to the traditional manufacturing processes where everything was based upon the higher amount of wastages. Hence, any kind of waste plastic can also be recycled for future uses which are another great benefit for this particular system and makes this very much environment friendly.

-The plastic inserts or metal inserts can also be easily molded with this particular system then people will always have good control over the color related things. Everything will be based upon a higher level of consistency which is another great thing and there will be a high tolerance level along with proper reliability all the time.

Hence, whenever the injection molding will be implemented with the help of double injection molding then finishing will be very smooth and ultimate product will be very much good in terms of enhanced strength. These kinds of things will reduce the density of plastic waste and will add great strength to the ultimately completed part.